|

Shanghai Shuosen Mining Machine Co.,Ltd

|

dissolved air flotation machine

| Price: | 5000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

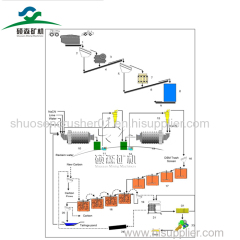

Applicable materials: gold ore, iron ore, copper ore, molybdenum ore, aluminum ore, lead ore, talc, coal fluorite, bauxite, potassium feldspar...

Application fields: For the selection of non-ferrous metals, ferrous metals and non-metals.

Processing ability:0.18-20m³/min

Rotate speed:180-483r/min

Applicable materials: gold ore, iron ore, copper ore, molybdenum ore, aluminum ore, lead ore, talc, coal fluorite, bauxite, potassium feldspar, quartz stone, etc.

The Inner Structure and Application of Flotation Machine:

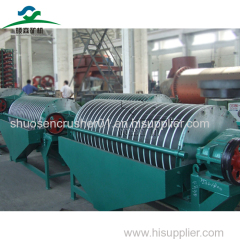

This flotation machine is suitable for separating non-ferrous and ferrous metals as well as non metals such as fluorite and talc.The structure of flotation machine: this machine is mainly composed of pulp chute, mixing device, air charging system, mineralized bubble discharging device and electro motor.

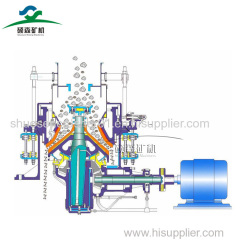

The Working Process of Flotation Machine:

This machine runs by the triangle belt of the electrical motor driving the impellor to rotate, producing centrifugal effect which will form negative pressure, and on one hand it will absorb sufficient air in order to mix with the pulp, and on the other hand it will mix the pulp in order to mix with the reagents, and at the same time will refine the foam in order to stick the minerals onto the foam, and float on the surface of the pulp in order to become mineralization foam. The workers can adjust the height of the flashboard and control the liquid level in order to scrap the useful foam.

Precautions of Flotation Machine

Before starting the machine, first check the bolts of all spare parts and before stopping the machine, manually spin the wheel to prevent the depositing of sediment from increasing the load of electro motor. During the working process, carefully adjust the height of the flashboard to maintain the stability of the liquid level, so that the mineralized bubbles on the liquid surface of the pump can be timely scraped to the launder. A certain space should be maintained between the impeller and the stator, and when the impeller is abraded, it should be changed timely, and the bearing inside the pump should be maintained every three month.

If you want to know more about our equipments details,please contact us

Shanghai Shuosen Mining Machine Co.,Ltd

.jpg)